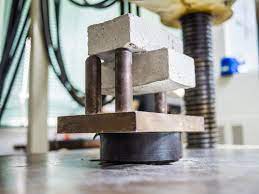

what is compressive strength of concrete| how to find compressive strength of materials

Compressive strength is the capacity

to oppose pressure loads. When all is said in done, utilizing RCA in the

substantial blend decline compressive strength contrasted with virgin total.

How ewer, at 28 days, all mix designs usually exceed 50 MPa compressive

strength. One study showed the compressive strength of virgin concrete

was 58.6 MPa and the RCA concrete ranged from 50.9 to 62.1 MPa.

There were higher values for

concrete made with 50% RCA compared to 100% RCA. The deficiency of compressive

strength is in the scope of 30-40% for the substantial made with RCA at 28

days. There was a minor reduction in 28 and 56 days compressive strength when

virgin aggregate was partially replaced with RCA and a much greater reduction

when RCA was used in full.

The most influential parameter

affecting compressive strength in the w/c ratio. Other influential parameter

include fine RCA content, cleanness of aggregate, interaction between fine RCA

content and crushed brick content and interaction between w/c ratio and coarse

RCA content . Keeping a constant w/c ratio, air-dried RCA containing concrete

had the highest compressive strength compared to oven-dried and saturated

surface dry RCA. Using unwashed RCA reduces compressive strength particularly

at lower w/c ratios. Compressive strength is 50% of virgin concrete at 0.38 w/c

and 75% at 0.6 w/c.

When comparing laboratory made RCA

and field demolished RCA, there was the same basic trend in all strength

developed. Admixtures in the original concrete has no signification impact on

the compressive strength of the new RCA concrete. At the point when slag is

added to the RCA concrete, it creates strength throughout a more extended

timeframe contrasted with ordinary cement.

Some research suggest

that compressive strength is dependent on the amount of time the RCA spent in

the stockpile after crushing. For example, concrete made with RCA that was in

the stockpile one day had a 25% higher compressive strength than concrete made

with RCA that was in the stockpile 28 days. Concrete made with RCA that was in

the reserve seven days had a seven percent lower compressive strength than

substantial that was in the store 28 days.

RCA concrete showed good

performance when exposed to temperatures up to 600 C with a loss in compressive

strength of 20-25%. When RCA concrete fails it is usually because cracks passed

through the RCA: however, when virgin concrete fails it is usually due to bond

failure at the aggregate paste interface.

There are several barriers to overcome in order for

RCA to become widely accept. Initially there is high investment cost to

purchase concrete crushers. In addition, maintenance cost of concrete crushers

is significant.

As reasonable obstacles are present if crushing of

concrete is done by concrete crushers. Similarly problems are there if crushing

process is done by man power. Both these methods of crushing have their

advantages and disadvantages. Machine

crushing has advantage of smooth crushing but increase the cost which is major

concern in the project.

On the other hand, manual crushing has advantage

according to the major purpose of the project i.e., cost but having

disadvantage of ineffective smoothness in crushing aggregate and chance of

breaking of aggregates particles into small pieces. So, there are some problems

identified during crushing

There is a problem to make the RCA surface free the

mortar mechanically or manually for its proper usage in the concrete to make

bond. If the surface is not free from mortar than its bond become weak and it

gives no better strength.

Another complication is related to quality of RCA. Highways

require quality material that meets engineering, economic an environment

consideration. RCA cannot be used where high performance is required,

Concrete that RCA has less compressive and flexure

strength, increase dry shrinkage. There is also lack of knowledge on how RCA

affects durability.

Government agencies have been show down to embrace to use of RCA due to concern about quality and reluctance to change the past practices. The use of material specification is a crunches in use in RCA. However, specific standards to use RCA in new concrete are not currently available

0 Comments